Enhancing HVAC performance through CFD simulation

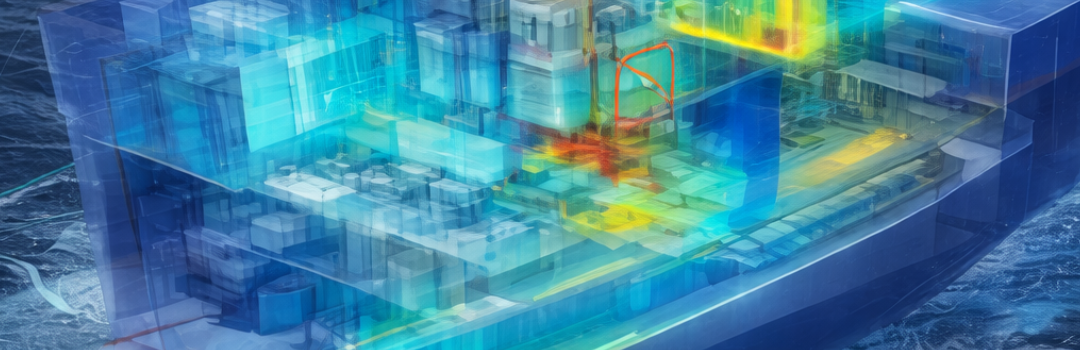

Smart engineering can turn complex thermal challenges into clear operational improvements. When a customer required deeper insight into onboard thermal conditions, a CFD analysis was conducted to map airflow patterns and temperature distribution within the engine and generator rooms of a large vessel.

On the lower decks, rising temperatures made it critical to understand how cooling air moved through the vessel’s layout. In collaboration with Novenco Marine & Offshore, a CFD simulation was carried out to evaluate airflow behaviour across multiple decks.

The outcome was an optimised ventilation design that delivers cooling air exactly where it is needed most:

- CFD-verified improvements in airflow

- Minimum 10 °C temperature reduction across all rooms

- Improved HVAC performance in demanding marine environments

- Enhanced protection of critical machinery

By digitally simulating the thermal environment, the effectiveness of the new ducting and ventilation layout could be validated prior to implementation — ensuring safer, more efficient, and more reliable onboard operations.

This project demonstrates how detailed insight into airflow behaviour enables informed HVAC decisions and measurable performance improvements in complex maritime environments.

Read the full case to learn how detailed CFD analysis enabled informed HVAC decisions and measurable performance improvements in a complex maritime environment here.